Quality inspection is a very important part of the quality control of product. Today, I will take you to see the quality inspection department of Yaoshi New Materials and see what work needs to do in the quality inspection department daily.

Let's visit the polishing workshop of Yaoshi New Material's together,and see the daily work of the staff of workshop

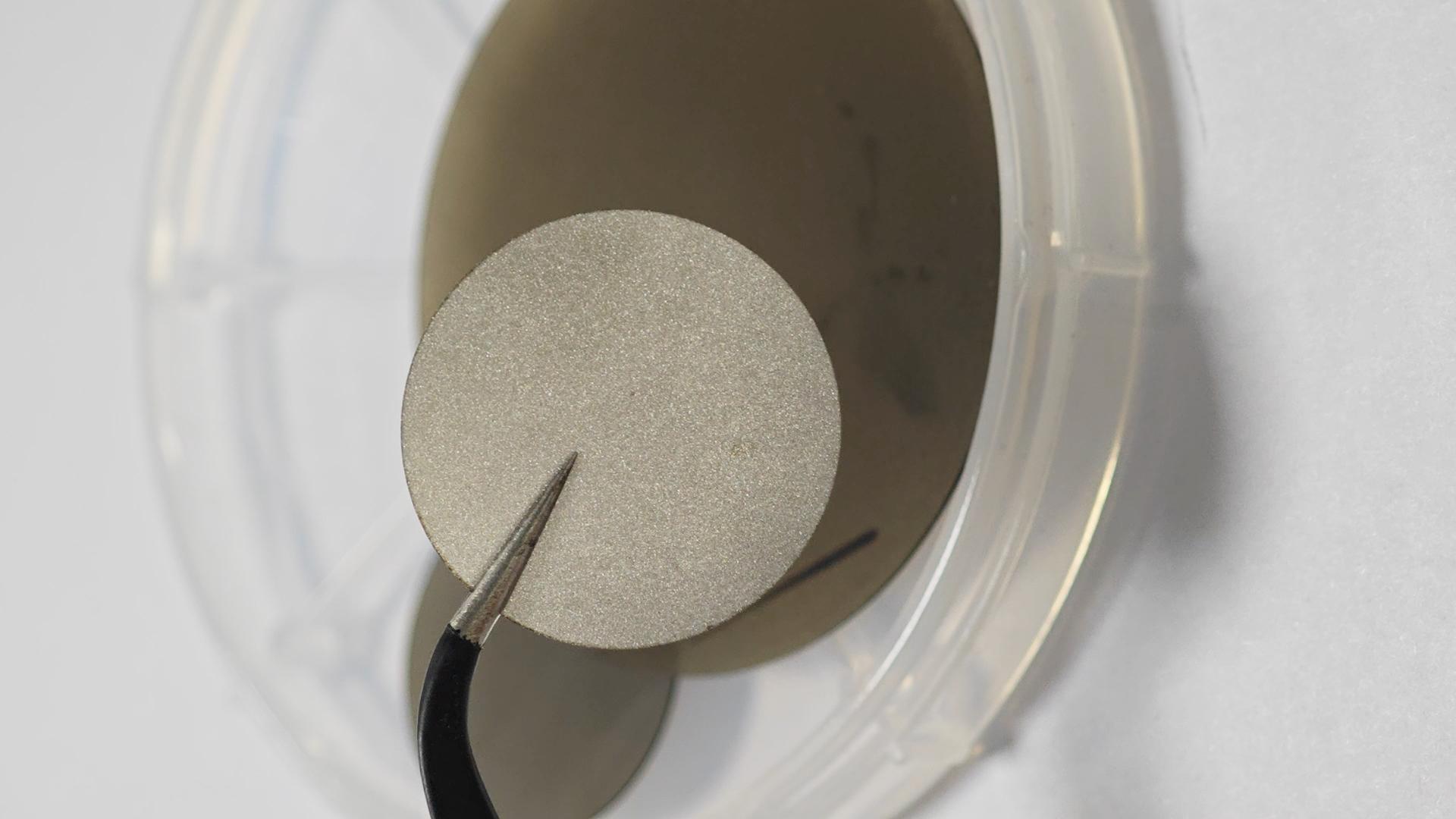

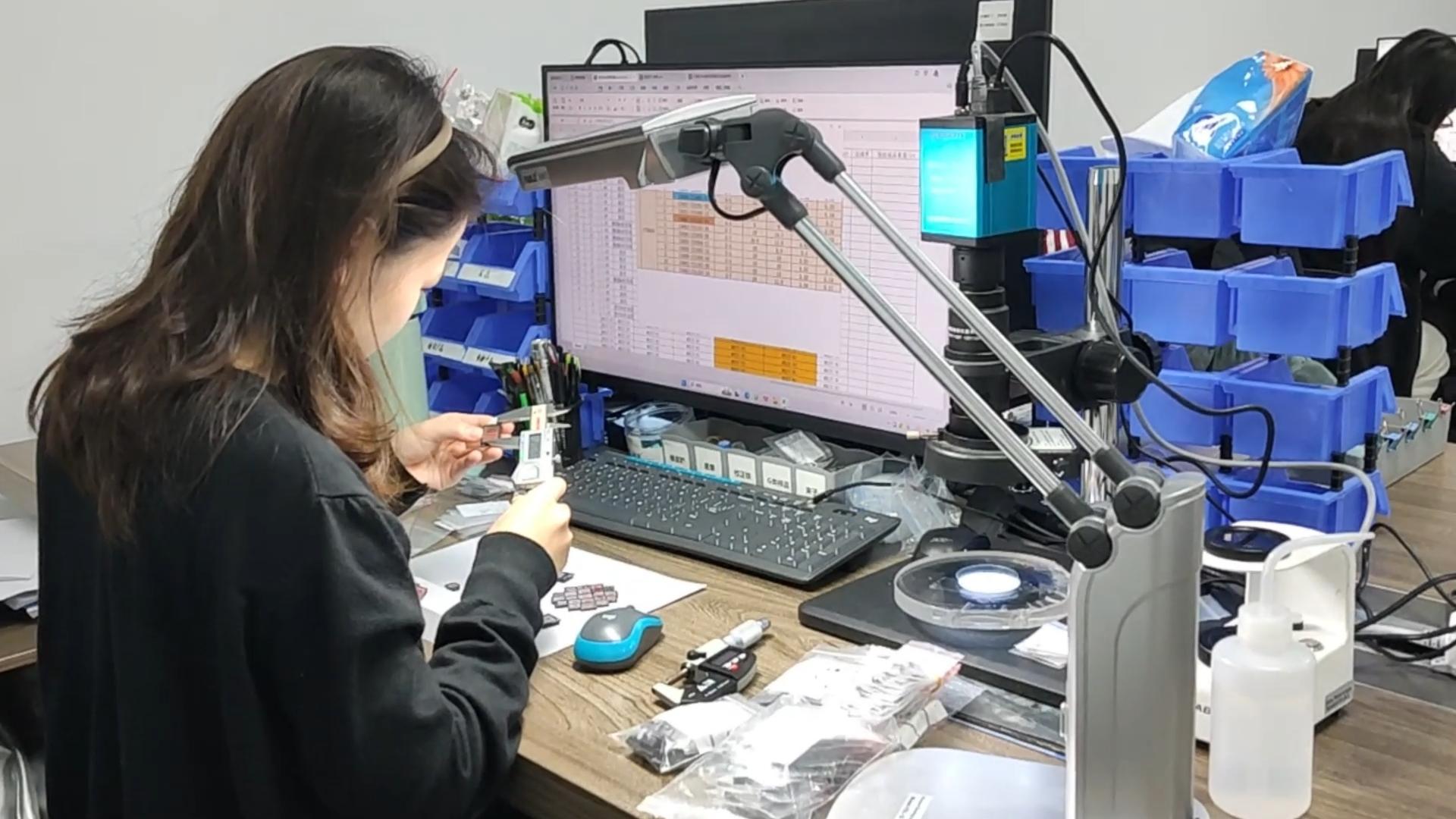

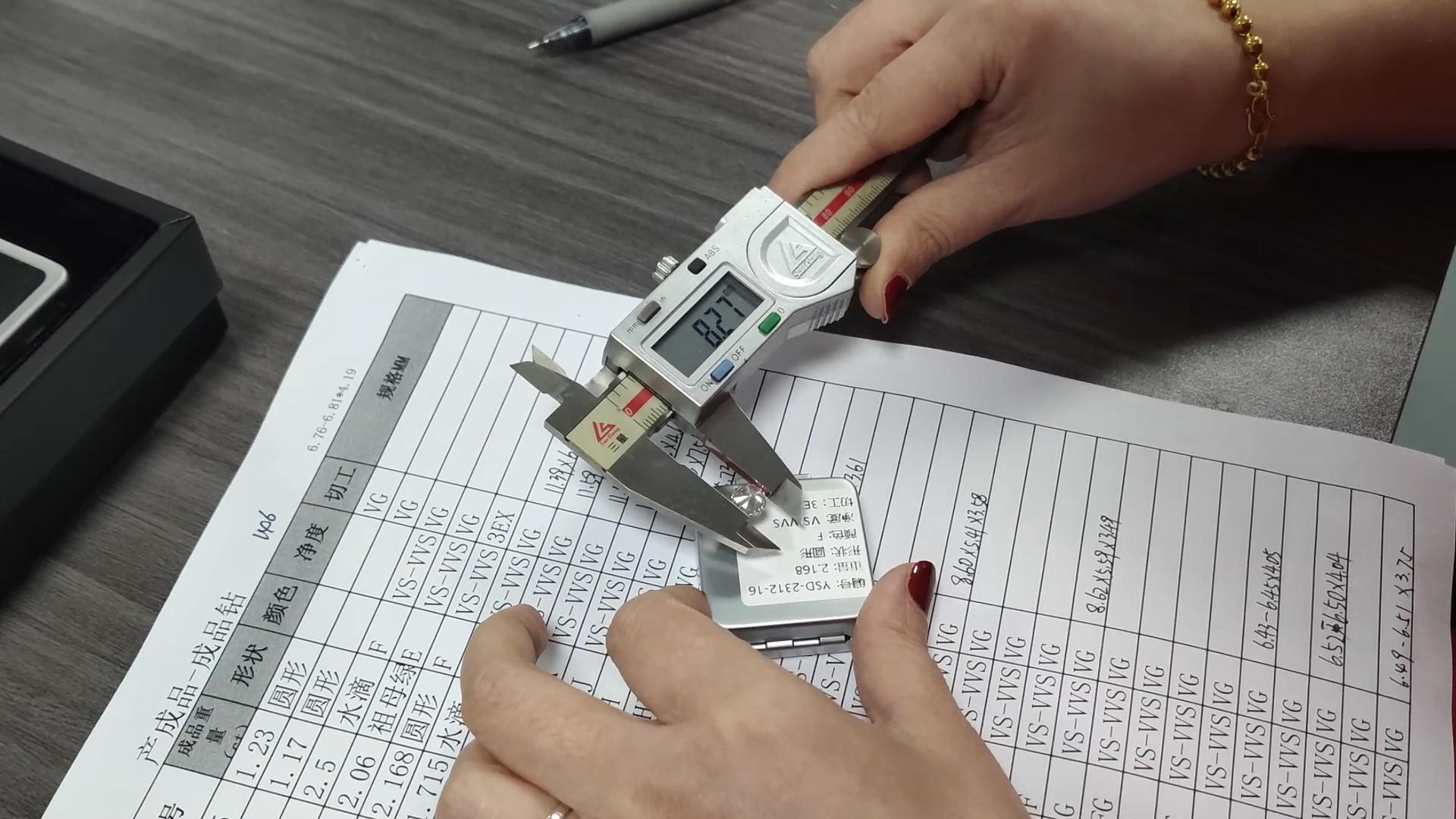

Every CVD rough diamond goes through a rigorous screening process.The measurement of length, width and thickness is one of the important and common work.

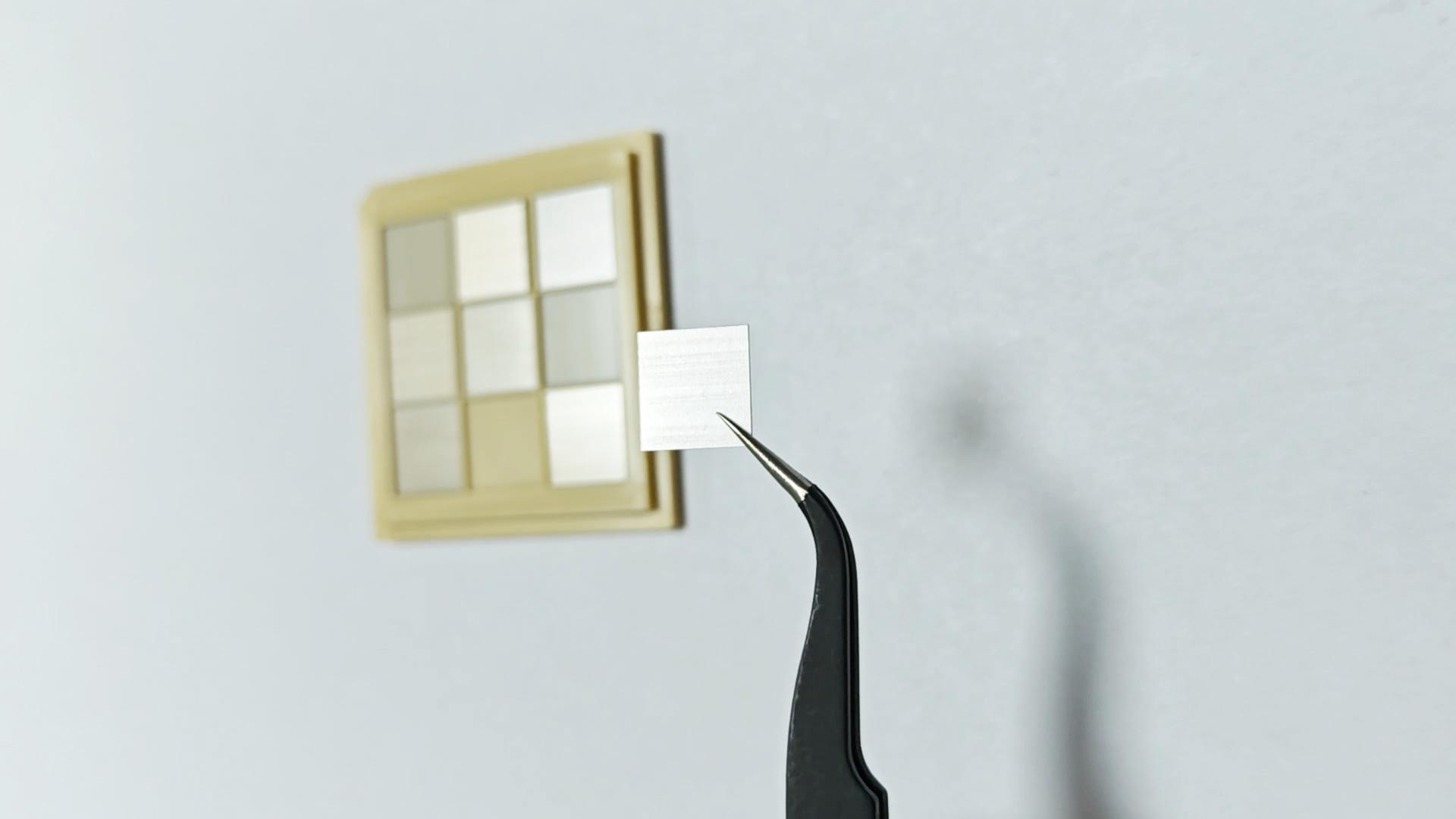

In addition to the size, the color also has strict requirements.The rough diamond with colorgrade above G will enter the next part.

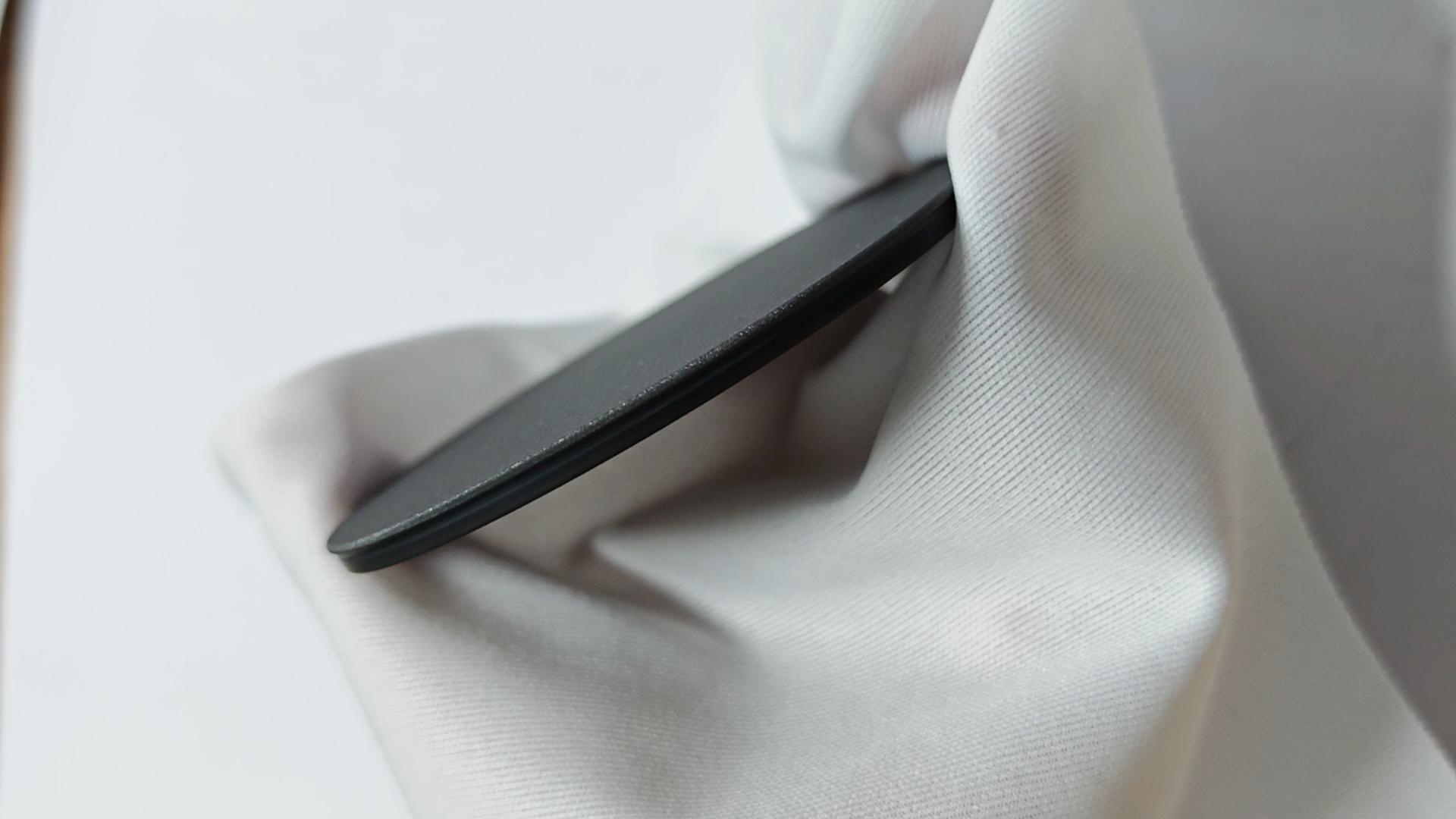

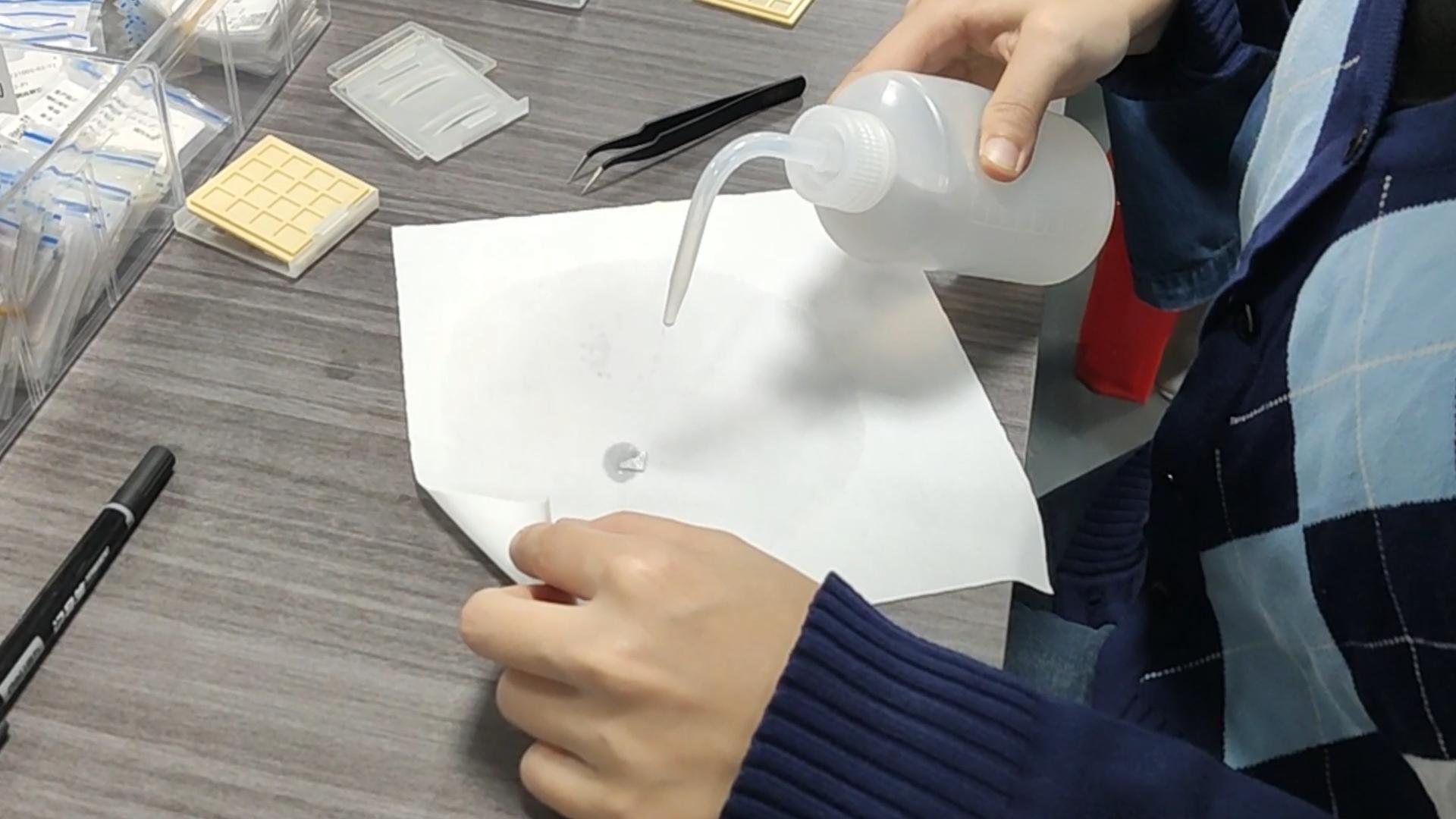

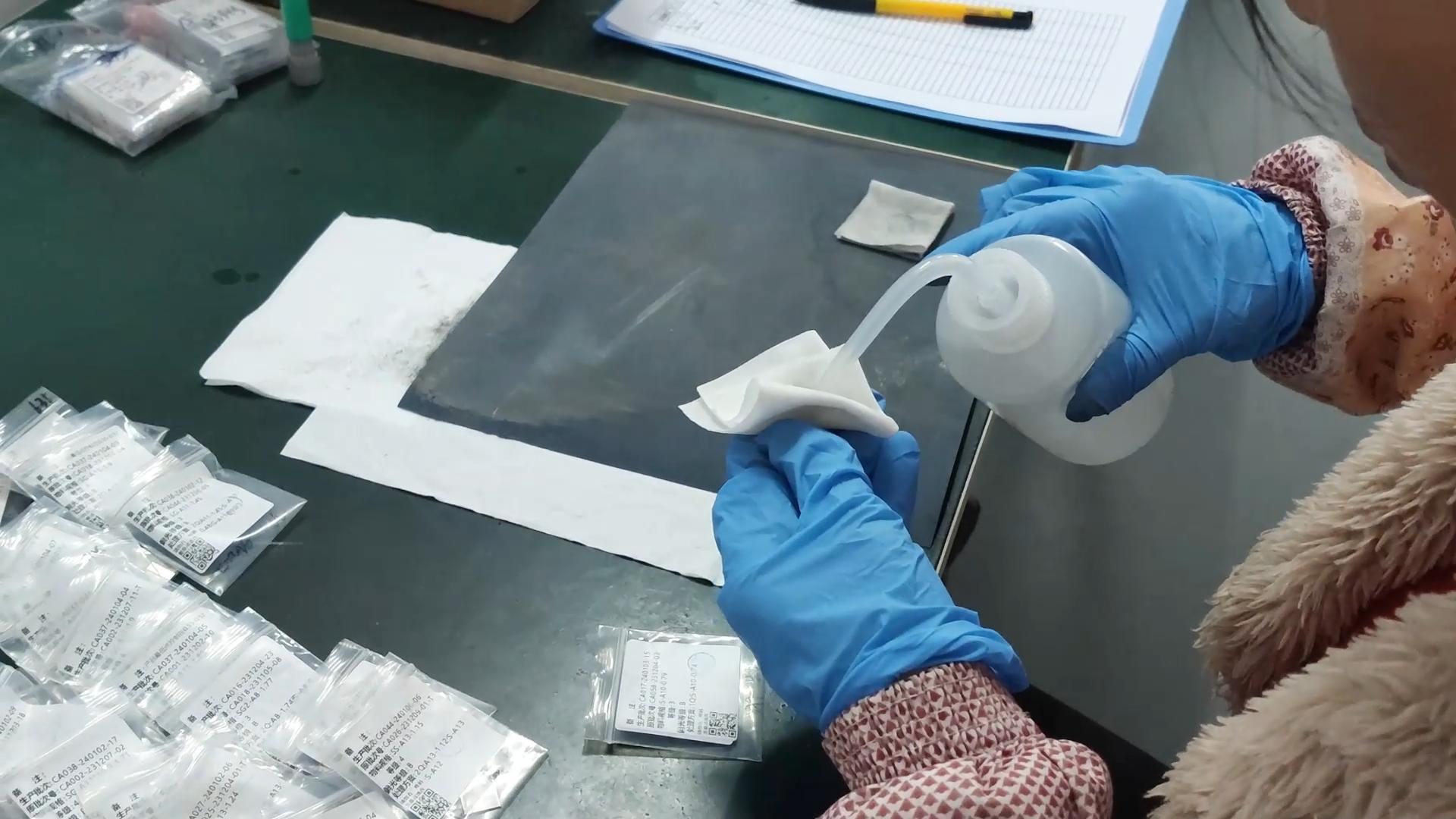

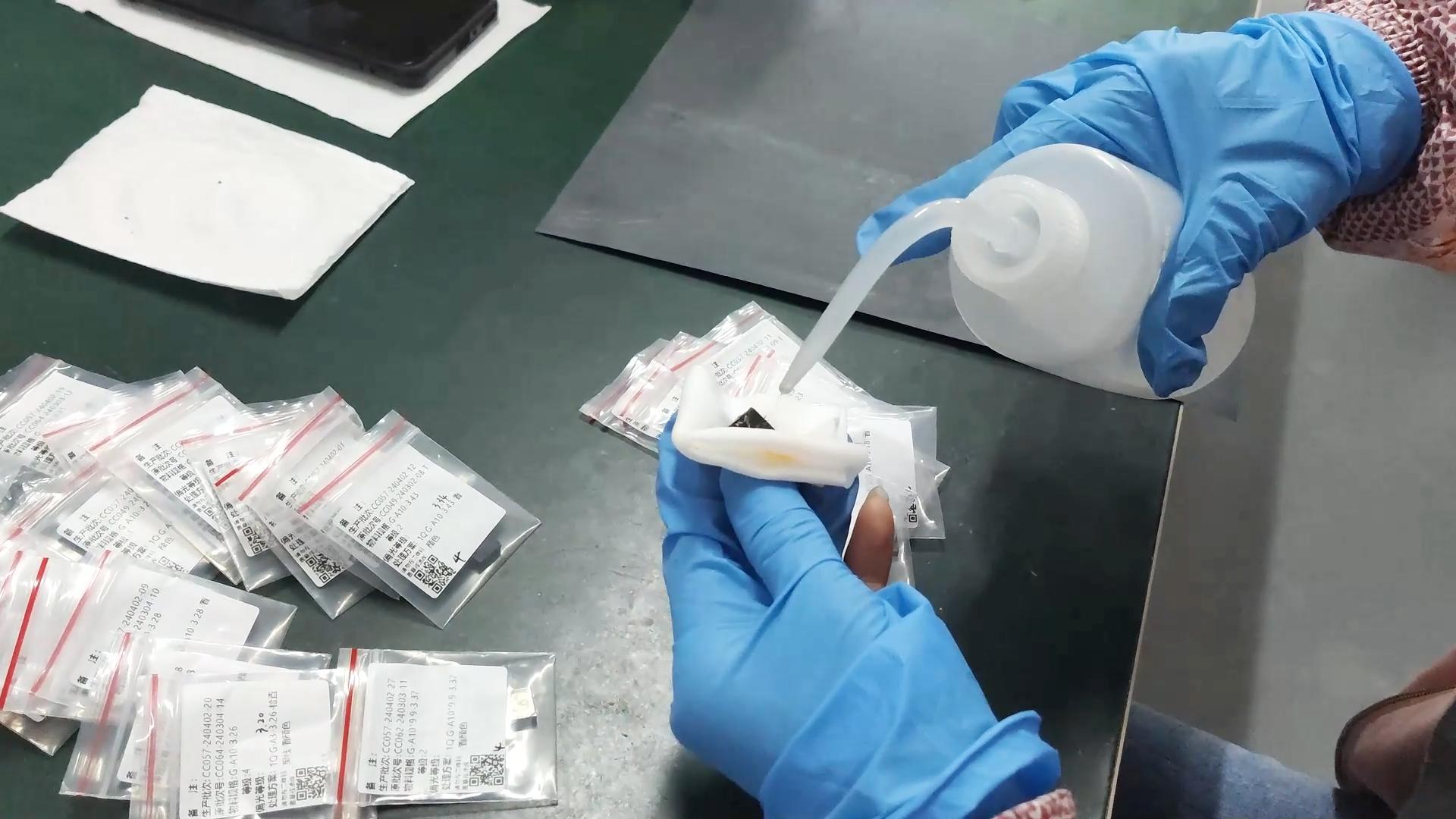

Alcohol cleaning, cleanroom wipers drying, this is the necessary process before shipment of wafer.In this way, impurities and oil stains attached to the surface of the wafer can be better removed

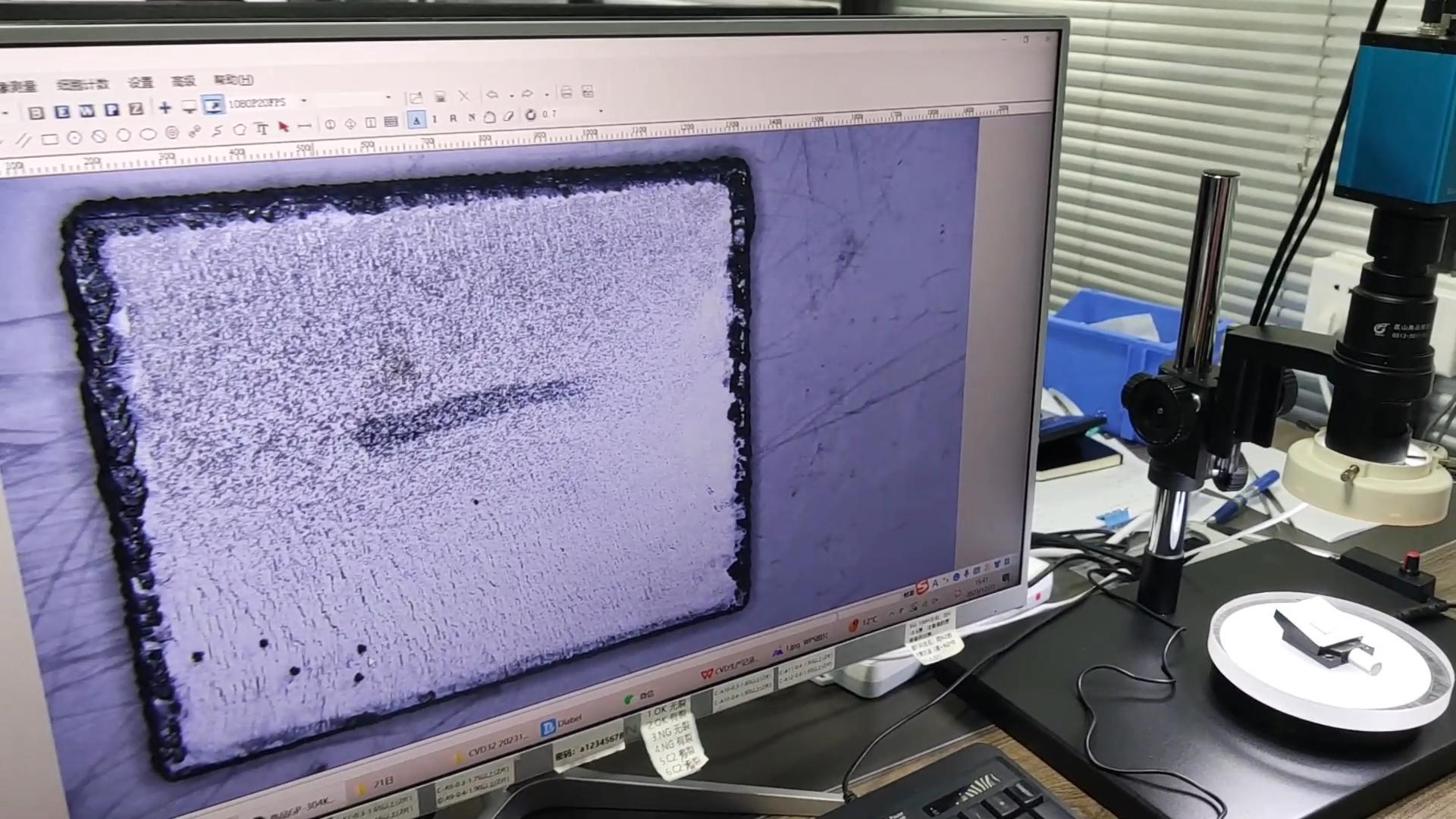

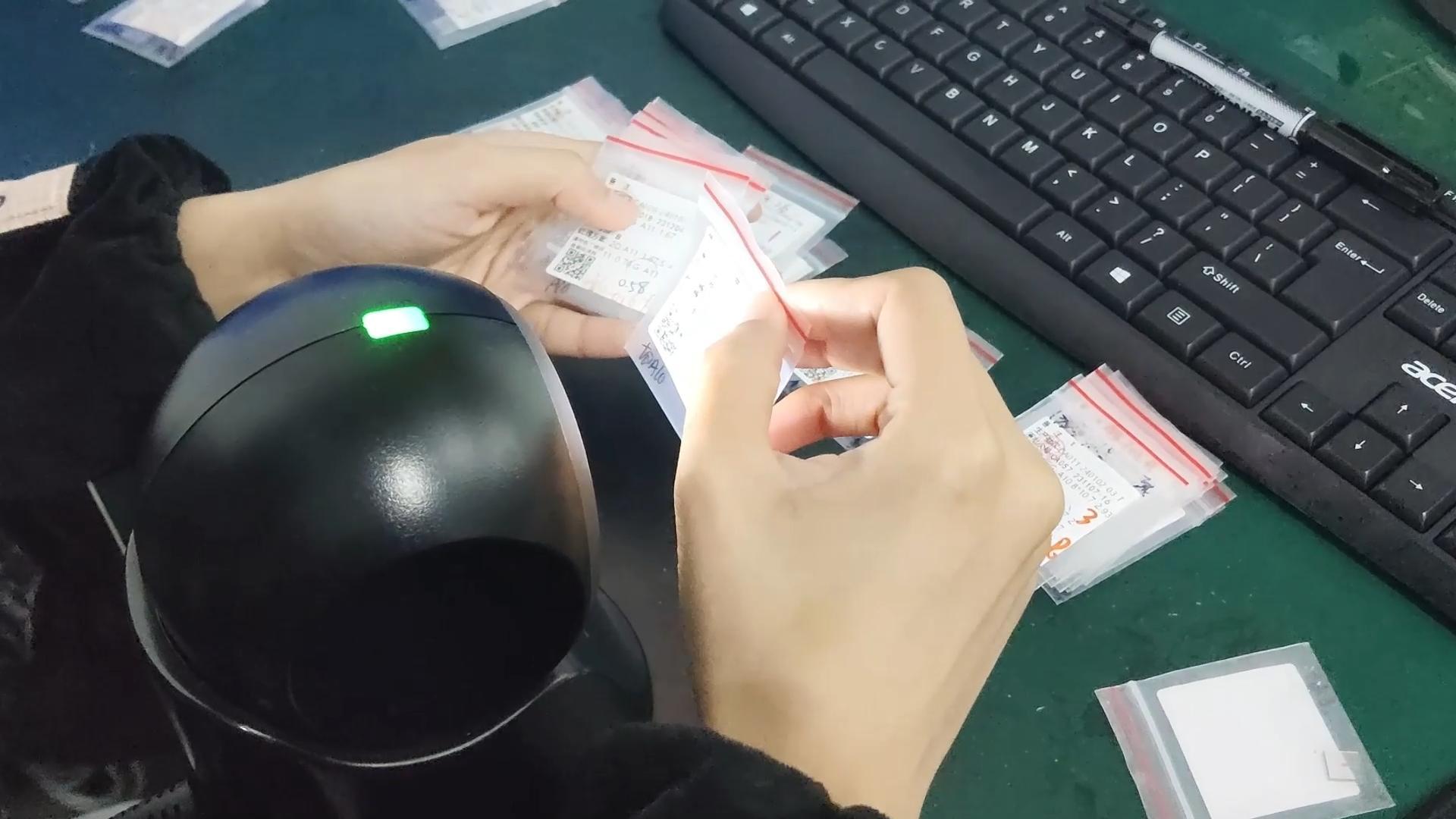

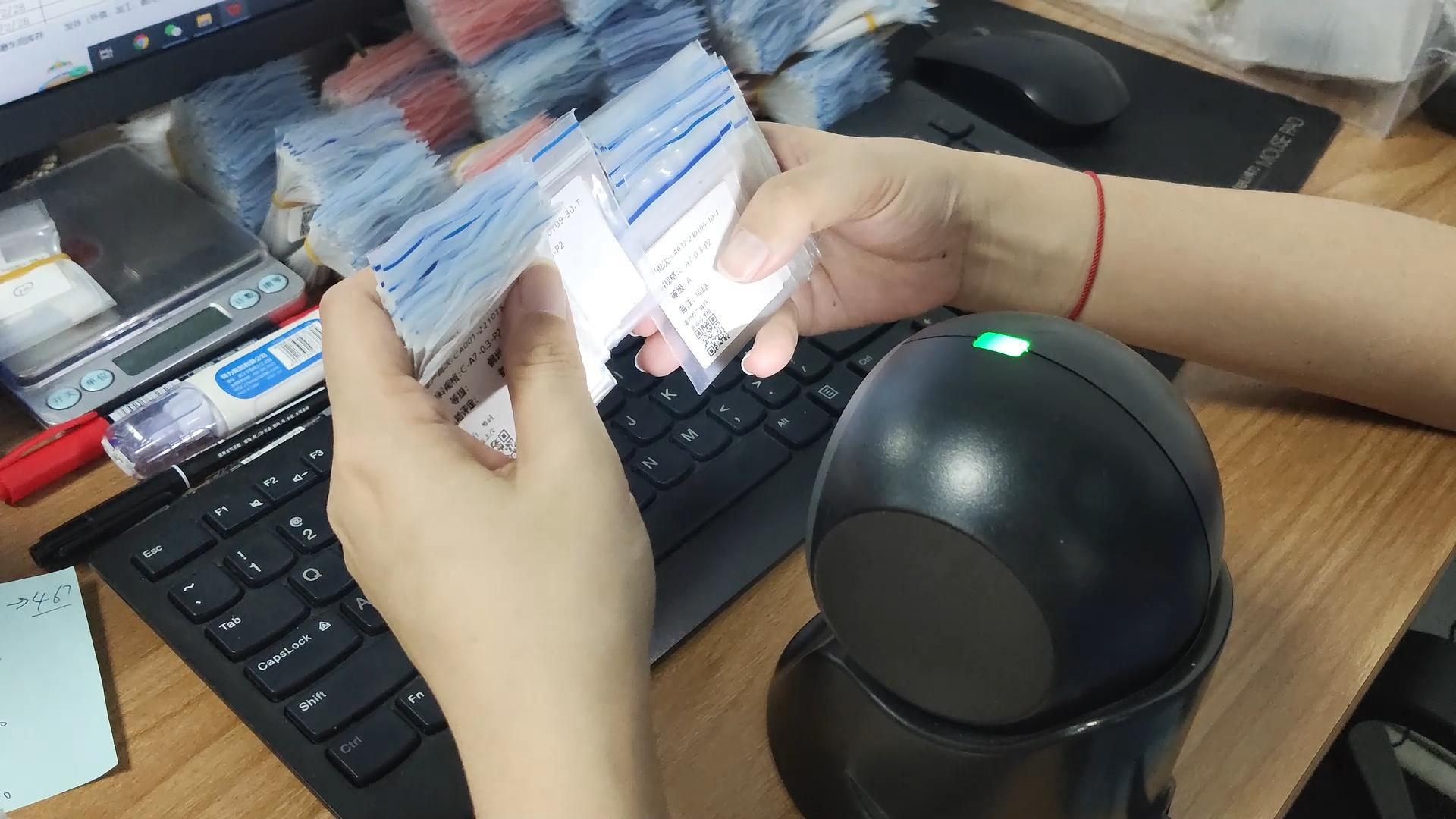

The cleaned wafer need to be checked again before they can be shipped.From preparation to delivery, the product is checked several times to ensure quality

The wafer inspection is a necessary process to ensure the quality of the product. The content of the wafer inspection includes: black spots, scratches, cracks, potholes and other defects. After many checks, the wafer of good quality will be sold

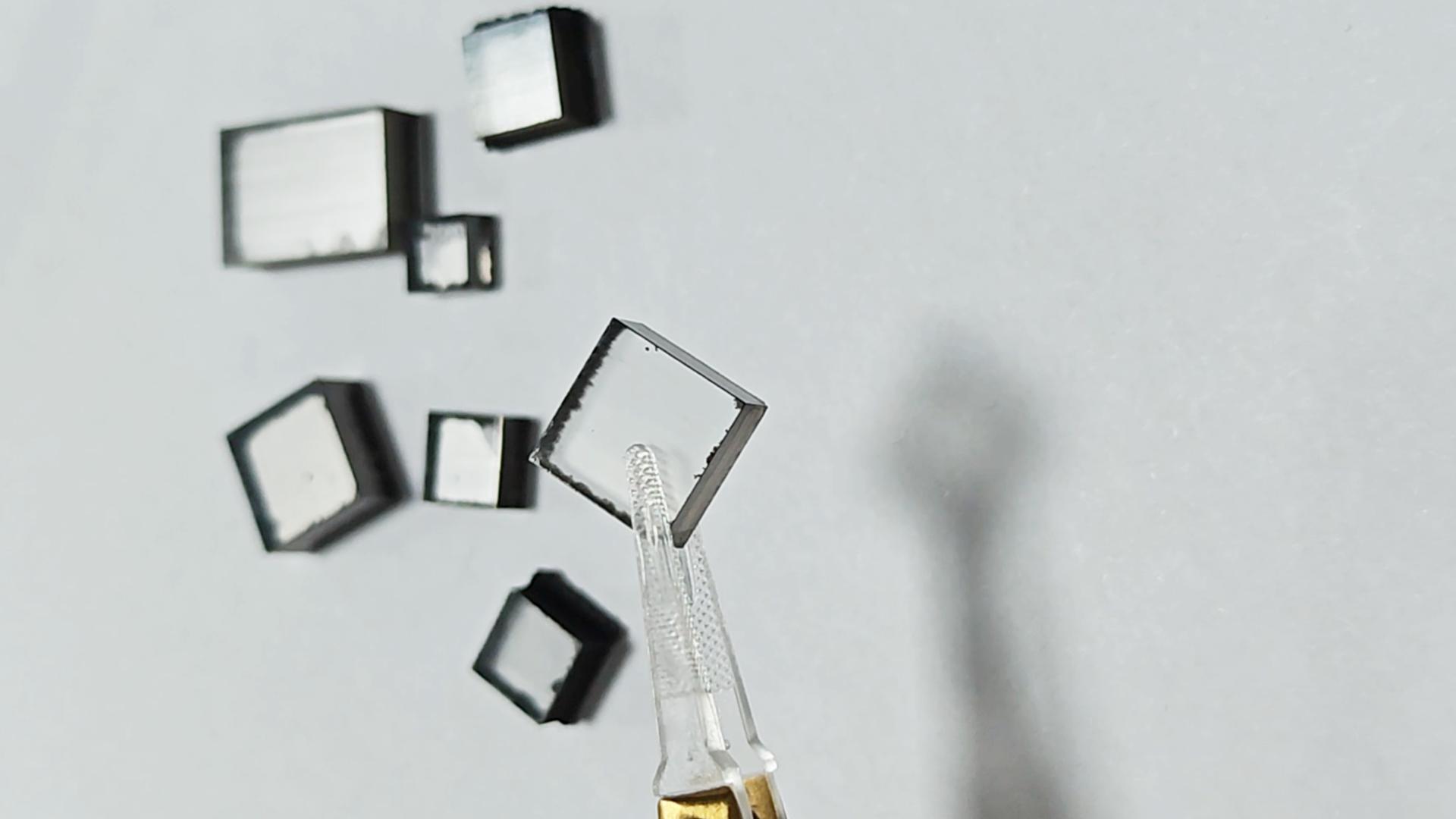

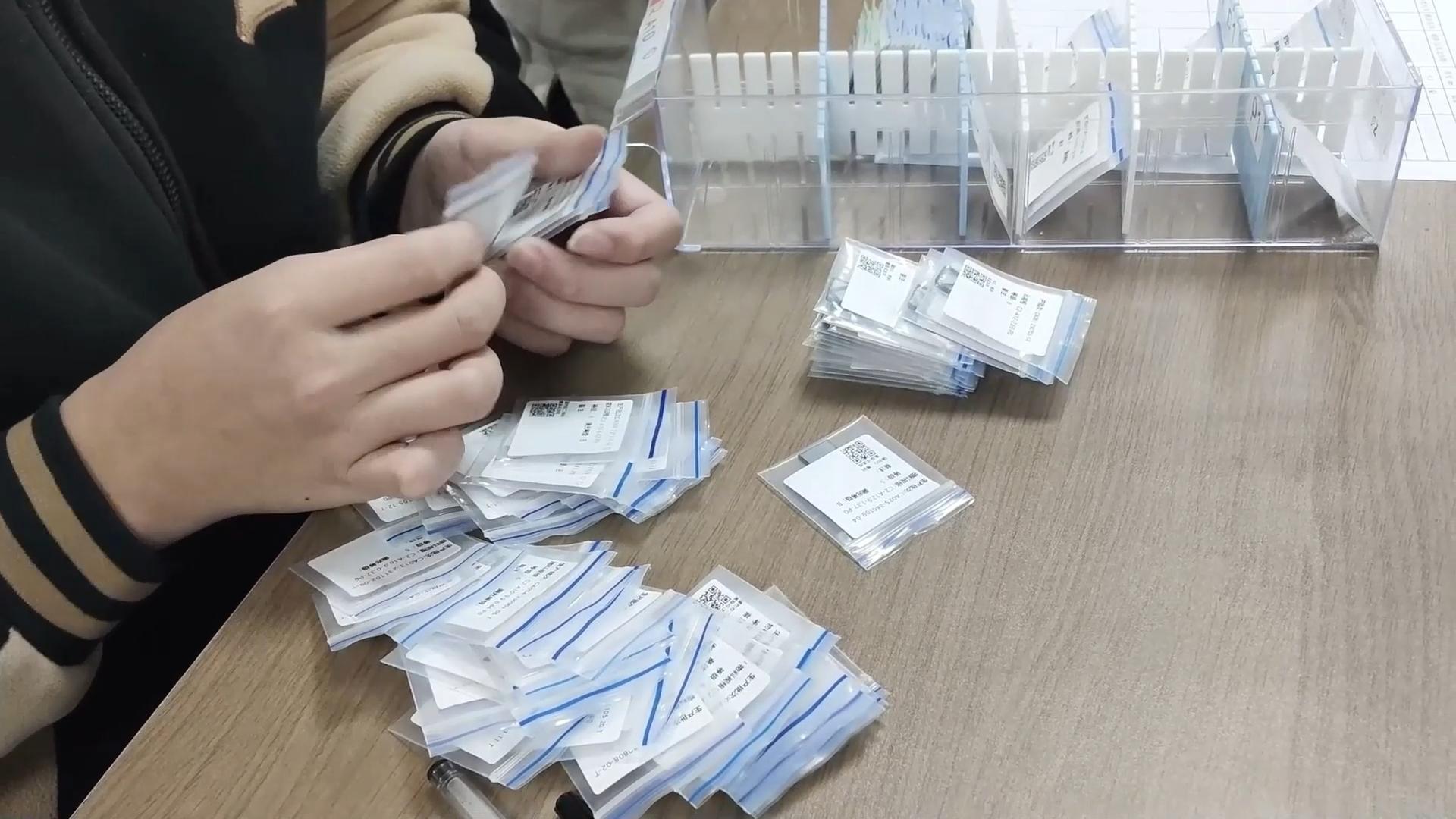

Diamonds after processing need to check their numbers, shapes and 4C parameters.The 4C refers to weight, color, clarity and cut.

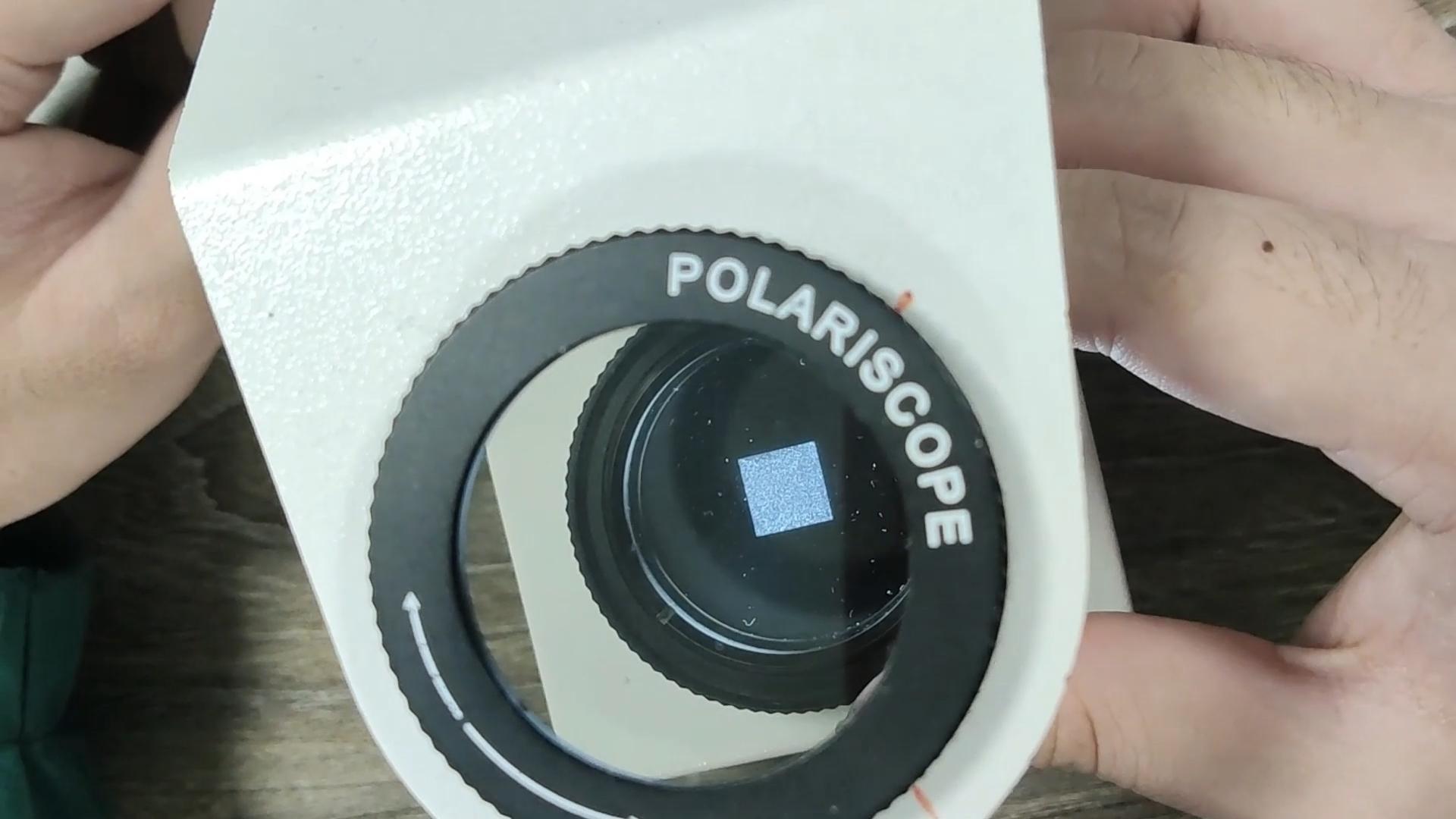

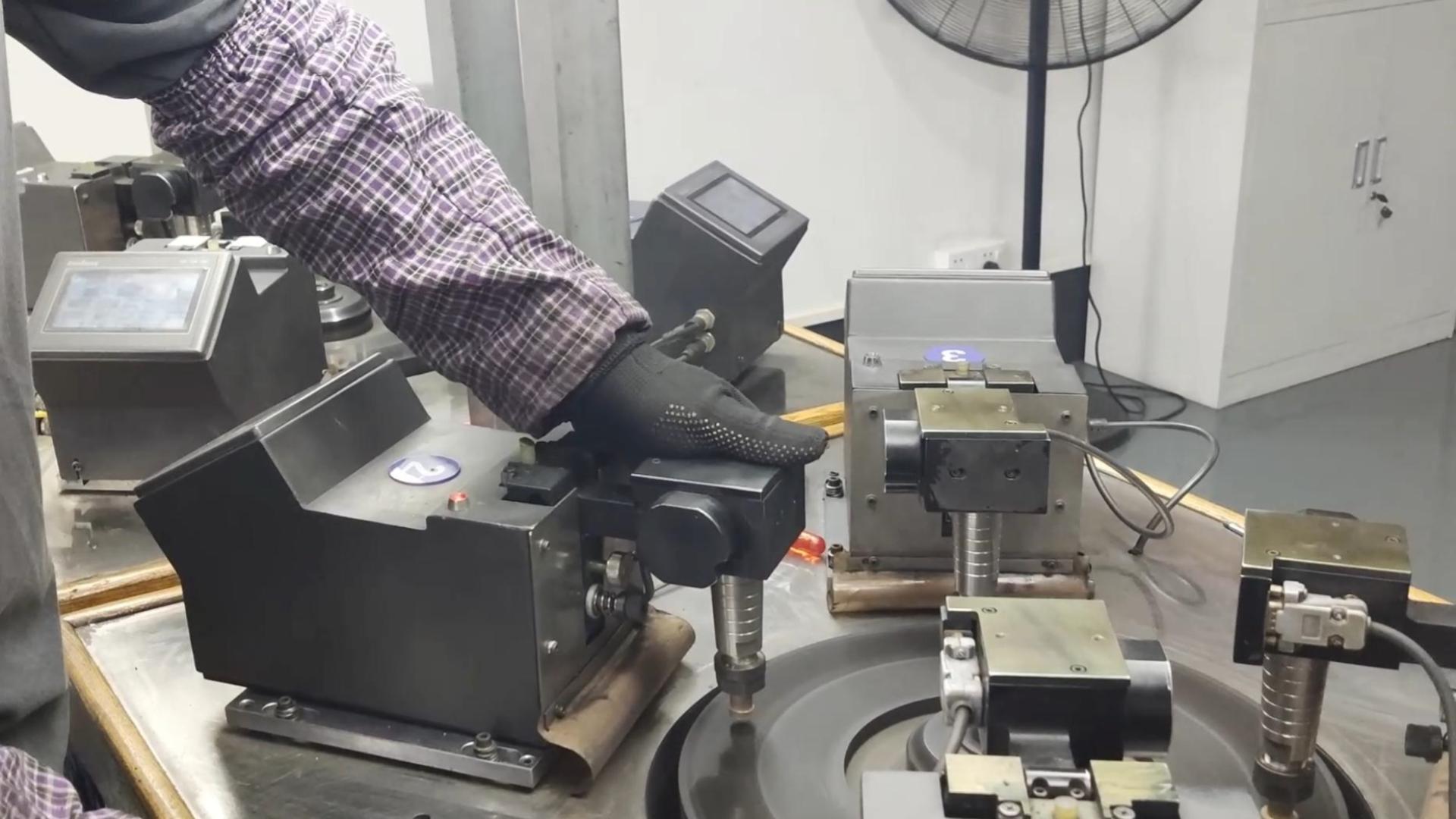

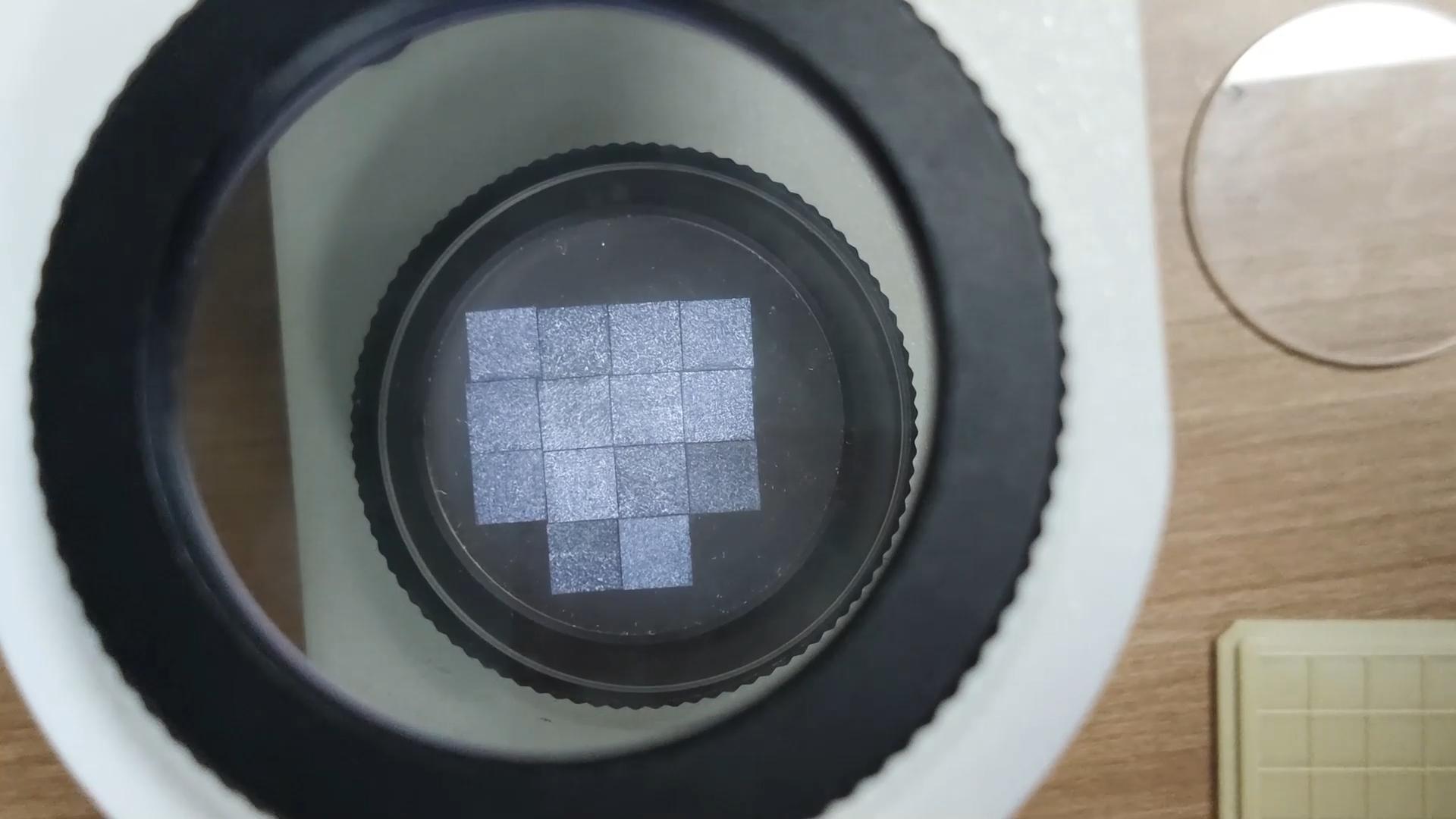

Polarization is an important indicator of determining the quality of the wafer.Determine its polarizer level based on whether its polarizing is evenly

Determine its specifications by measuring its size.Our compian's CVD diamond wafer has complete specifications and sufficient inventory, please consult if you are interested

To maximize the use of rough diamond ,the plan must be issued according to the actual situation of the rough diamond.

The diamonds that are processed, in addition to checking their 4C parameters, also need to measure its size. In order to ensure the correctness of the data, the data on the processing table will also be reviewed

After the wafer is cut, its surface may adhere to carbon powder or impurities. In order to avoid subsequent processing, it is necessary to clean the surface of wafer.

The cut wafer also needs to be grinded. Polishing the Wafer can reduce the surface roughness of the wafer. Mechanical polishing is currently a large amount of diamond polishing method.

Product warehouses are an important and indispensable task for production material management. Each product produced in the workshop needs to be registered in the warehouse.

The products and production materials are invested every month.Determine the current amount of the product,check the error and modify it in time.

The product before shipment, except to check whether the product is flawed,Will check the polarization of the product ,Make sure the products before shipping have no quality problems.

Materials need to go through many processes from exempting to finished products,In order to maximize use of materials, processing

must be processed according to treatment plan.Confirm the material specifications is an indispensable job to issue a processing plan.

Like the wafer, the surface of rough diamond may be adhered to carbon powder or impurities after cutting,Avoid affecting subsequent processing, cleaning on the surface of rough diamond is essential.

With the sales of product, the product needs to be out of the warehouse,Product outlet is a crucial part of inventory

management.